A common problem in any industry is inefficient management of packaging materials. Many industries may be concerned about bringing this part of the business under micromanagement, as it is very often difficult to get good enough real-time tracking of what has happened to the packaging material after shipment. Many companies are committed to reusing packaging materials throughout the process, but there is still a problem getting any data on this. And we need such data.

There is no denying that during the last two years of the global crisis, the market has been affected by the shortage of resources for paper boxes. Currently, there is sufficient alternative to replace paper packaging materials in any type of distribution and prodcution. Making the decision for a company to shift to returnable packaging materials can be very important from an enivroment perspective.

Therefore, every company operating in the market should consider a new approach to effectively manage packaging materials. A smart approach to these matters can have a significant impact on improving financials in supply chain and help a company avoid downtime.

Comply with requirements for packaging materials

Optimization of the reusable returnable packaging material process in supply chain is more than required to prevent the mentioned incidents. There are companies that offer separate software to handle several tasks within an operation. Nevertheless, several may be able to implement simultaneously multiple solution in operations and transportation and many others areas.Novacura Flow is software that can provide flexible digital solutions in the most well-known areas of distribution, manufacturing and other industries. One such solution is the fully digital management of packaging materials controlled by Novacura FLOW software.

The system for returnable packaging material, from Novacura Flow, is packaging optimization software that enables packaging control throughout the supply chain and beyond, giving users:

- a complete digital overview of the ongoing cases

- real-time tracking of consumables and products

- digital solutions for internal and external administration returnable packaging

Optimal packing material management

Optimization of the reusable returnable packaging material process in supply chain is more than required to prevent the mentioned incidents. There are companies that offer separate software to handle several tasks within an operation. Nevertheless, several may be able to implement simultaneously multiple solution in operations and transportation and many others areas.Novacura Flow is software that can provide flexible digital solutions in the most well-known areas of distribution, manufacturing and other industries. One such solution is the fully digital management of packaging materials controlled by Novacura FLOW software.

The system for returnable packaging material, from Novacura Flow, is packaging optimization software that enables packaging control throughout the supply chain and beyond, giving users:

- a complete digital overview of the ongoing cases

- real-time tracking of consumables and products

- digital solutions for internal and external administration returnable packaging

Proven solution in returnable packaging loop

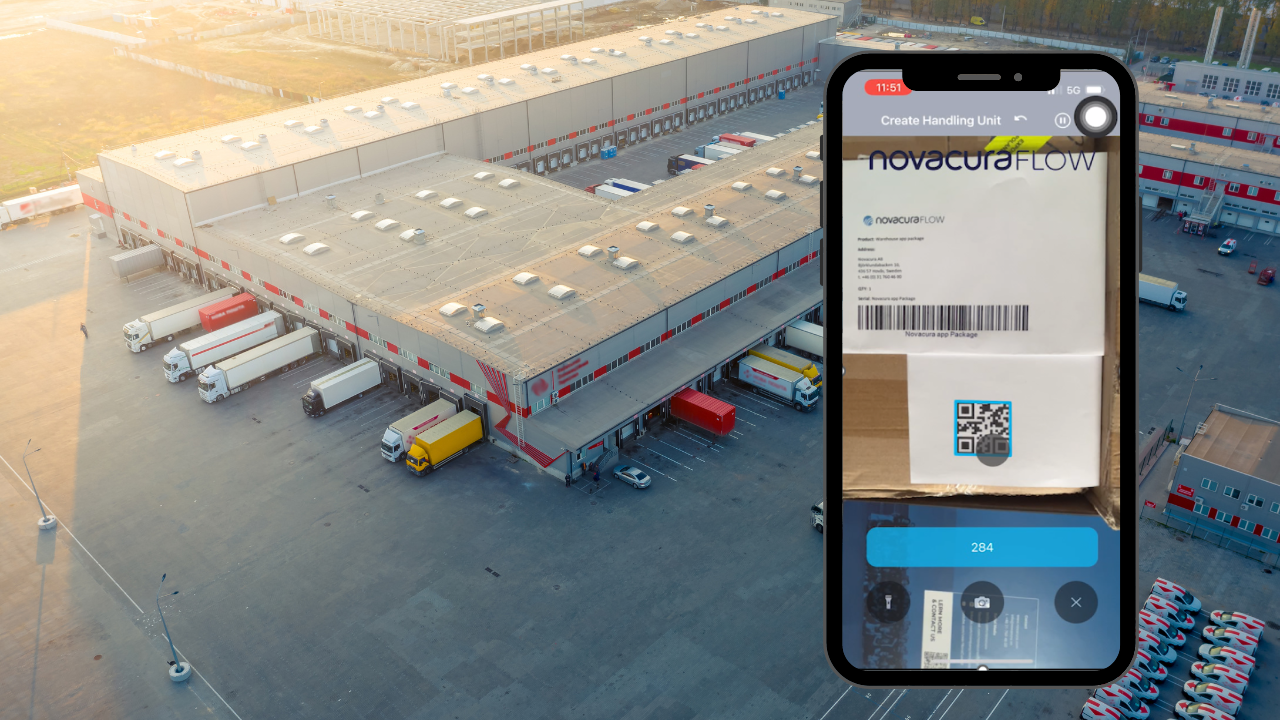

Novacura Flow software architecture has been developed for integration with ERP systems such as SAP, Oracle, IFS etc. Integration with Novacura Flow addresses all internal packaging material management needs, such as the inbound and outbound of packaging materials, from dockside registration, inventory control, order picking, delivery to destination and finally back to origin at the distribution centre.

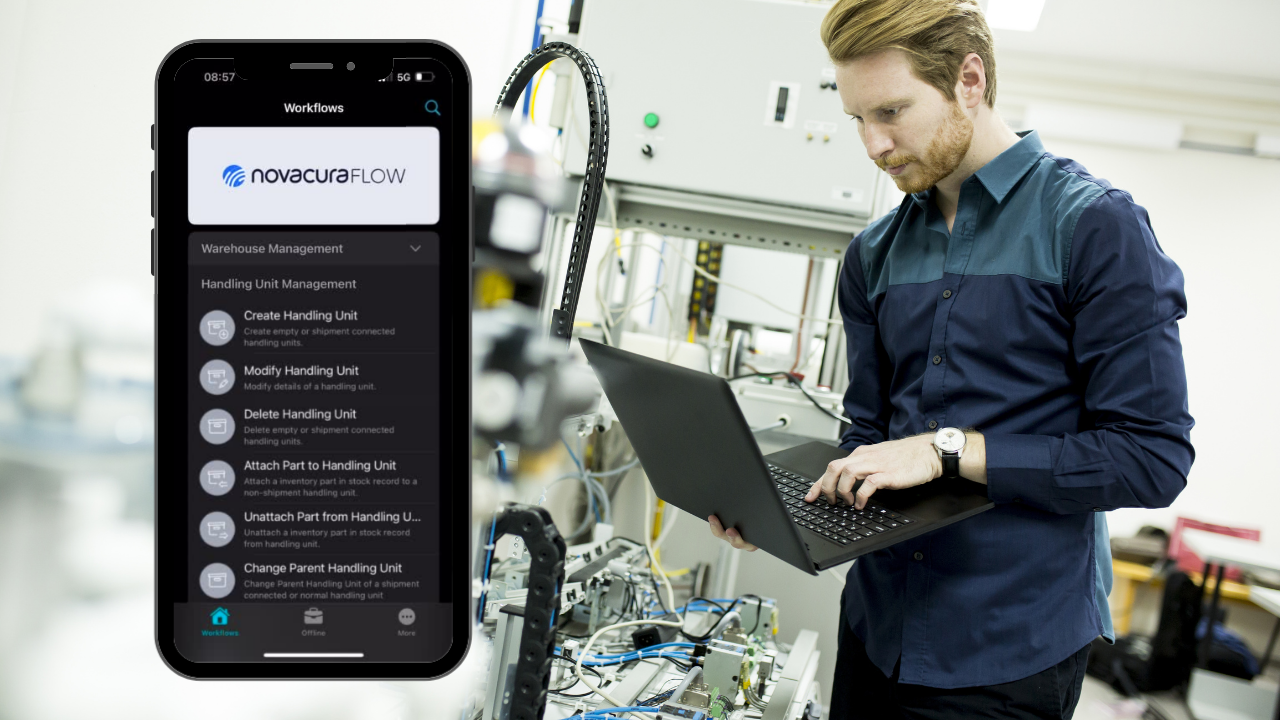

Novacura Flow software for returnable packaging material management may contain separate modules divided in relation to Standard Operating Procedures or Methods of Procedure. The operation can be equipped with a basic module for PC station users, applications for mobile users or a B2B platform for external users Supplier & Customer Portal. Novacura Flow can offer unlimited solutions for software implementation in the operations and transportation.

Total user control over the packing return process

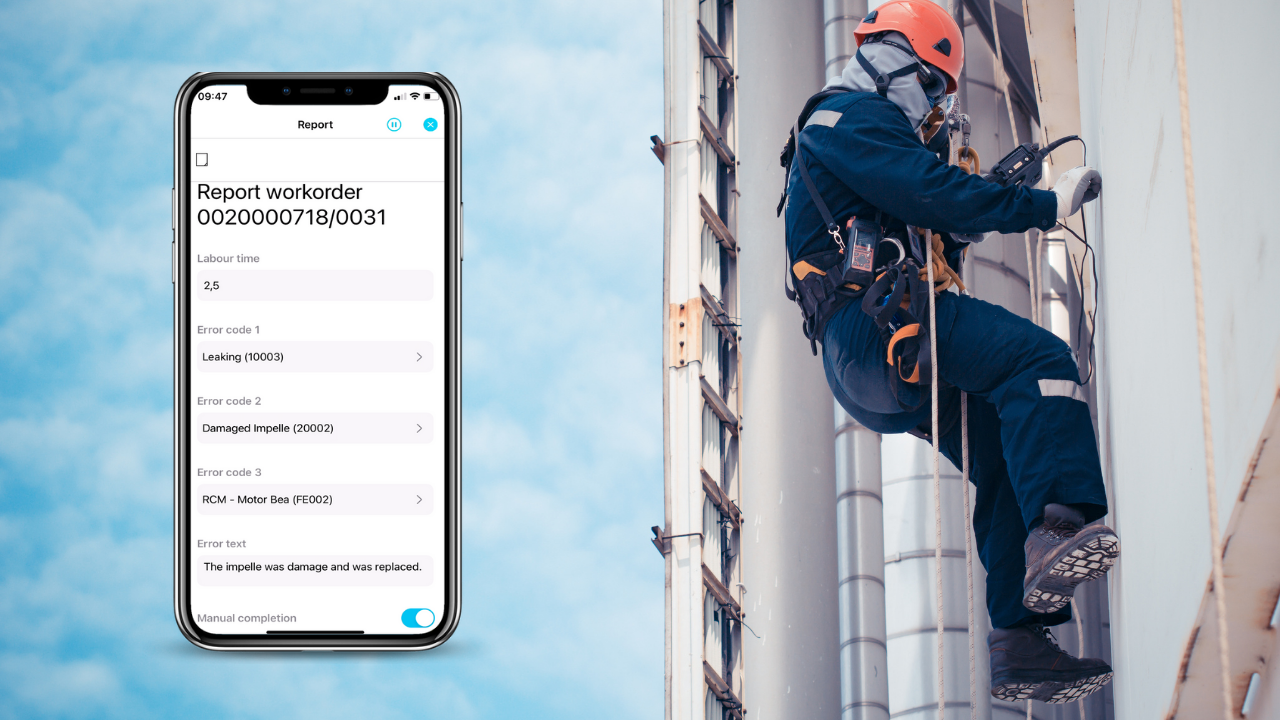

Users working on the shop floor can rely on the digital support of mobile devices and clear tracking of a single piece of packaging material, whether it is inserts in multi-component kits or plastic containers, large liquid tanks etc. The applications developed in the Novacura FLOW environment allow users to:

- generate of pick lists for packaging materials in reference to the required order quantity,

- allows all data to be saved in each user’s account,

- record stock of various events during the process: report damage, determining ownership of boxes etc.

- recognise the correct type of packaging material assigned to a particular product,

- barcode-based transactions using mobile devices (scanners),

Packing material traceability in transportation

Novacura Flow offers an essential solution for transport in packaging material loop. In order to secure the entire supply chain, the user can create a module for suppliers, customers and transport:

- Supplier & Customer Portal

This function enables the linking of carriers and suppliers as well as the sharing of expected delivery time (ETA) information between devices and departments. Access to the Supplier & Customer Portal allows inventory controllers to place direct orders for new supplies of packaging materials with ETA information.

Flexible reports system in packing material process

Novacura Flow allows the generation of multiple status reports supported by analytical charts. These rich features allow users to comprehensively analyse and quickly take action in case of a packaging material shortage or evaluate the entire reusable returnable packaging material process based on the data collected and archived. Sharing an example, an active users may use collected data for below purpose:

- estimate volume of next packing material order basically on usage or availability,

- take prompt action on root causes of damages and loses,

- effective manage available space in the storage area,

- evaluate ETA for packing material in the loop regarding the all transportation issues,

Reports can be generated for any emerging needs reported throughout the process. It is possible to convert the generated reports into MS Excel format. Novacura Flow offer well oriented solutions on the market and cover major gaps in the processes. Using Novacura FLOW in returnable packaging material process, users can expect number of advantages:

- Reduce the cost of product loss in the packaging material loop – healthcare, FMCG may lose products when short-term storage time is exceeded.

- Avoid consequences arising from contractual agreements – avoiding penalties caused by delays and downtimes.

- Mitigate the risks and reduce costs associated with the loss of retrunable packaging material – avoiding unexpected urgencies with premium freight due to an extra packing material reordering.

- Reduce transportation costs – optimal carrier planning for space in trailer and avoiding dead freight.

- Eliminate the risk of delaying operations due to lack of supplies – timely replenishment of packaging materials reported through the Supplier & Customer Portal.

- Reduce the number of the boxes in the distribution – purchase less of the packing materials and very transparent packaging movement.

These features allow users to fully optimize the supply chain on multiple levels and streamline the entire process according to individual business expectations.

Well integrated system of the returnable packaging management

Novacura Flow is able to provide a comprehensive returnable packaging material system implementation and provide users with a process modelling platform for Business Process Management. Novacura Flow uses Low Code technology, which allows users to flexibly modify the software at any time. The process modelling platform allows users to add new features and applications whenever an operational process has changed or requires additional support. Novacura Flow software contractors can count on ongoing support during the implementation process and respond to ongoing changes and needs in the future.

If you are thinking about long-term process optimization, Novacura Flow is a proven solution with more than 17 years of market experience and the expertise of specialists in various fields. With us you can achieve significant improvements in your area of operation, going far beyond an packaging material management. We offer software implementation at different levels and in different industries.