Öhlins Racing develops and manufactures advanced suspension systems for cars, motorbikes and the motorsports industry.

Their passion for innovation and high quality has made Öhlins a world leader. With distributors and Original Equipment Manufacturer (OEM) partners around the globe, information in many different systems and ever-growing requirements, the company’s logistics face tough demands from ordering and manufacturing through to final delivery.

Novacura spoke to CIO Arnold Hovén, who coordinates IT operations for the whole of the Öhlins Group.

Challenge I: How can we create flows for multiple systems?

Previously, Öhlins was dependent on several different systems to deal with aspects such as warehouse management and important product safety data. They were looking for a solution that could provide better control and a clearer overview.

Arnold Hovén, Öhlins Group, CIO

We identified a major risk in using in-house systems and external systems that had not been further developed. We’ve now reached a stage where everything that enters or leaves our warehouse is dealt with using Novacura Flow and reported to our business system, whether these are components or finished products, and whether they need to be sent to customers, scrapped or otherwise dealt with. Being able to work with different systems within a single flow is essential.

Previously, Öhlins was dependent on several different systems to deal with aspects such as warehouse management and important product safety data. They were looking for a solution that could provide better control and a clearer overview.

The different systems that had been developed both in-house and externally, linking the stock and product information with the business system.

Challenge II: How can IT support operations?

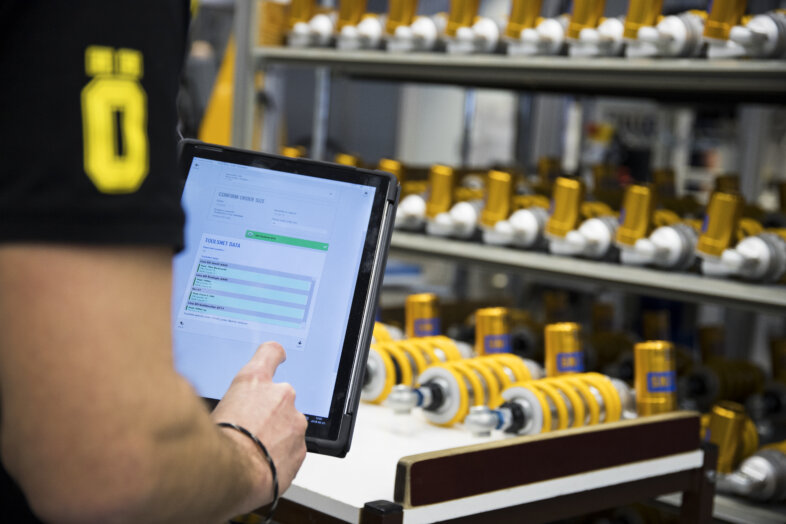

Arnold is particularly passionate about how IT can support operations. Öhlins has been using Novacura Flow for some time now with all inward deliveries and all outward deliveries – both for its shuttle system (automatic picking) and for finished products.

They currently use Microsoft Surface computers in their trucks, giving employees picking instructions to find the right location in the warehouse. The products are then scanned using handheld scanners and barcodes.

A colleague said it should be easy to do things right, and that’s something I firmly believe. We use IFS Applications™ as our business system. It’s incredibly powerful and competent, but can be complicated for occasional users not experienced in using the platform.

Novacura Flow is particularly exciting as one of its strengths is the ability to create steered flows, steering users to do things in a certain order and ensuring that they get access to exactly the options they need.

Challenge III: How can we provide customers and suppliers with better service and availability?

Another challenge faced by Öhlins is systems that don’t talk to each other when the company wants to offer partners and distributors a greater degree of self-service. The solution is a project through which Novacura Flow helps build a customer portal where customers can order the desired products themselves, even simultaneously from multiple factories.

Novacura Flow is an excellent tool when we need to obtain and record information in several systems at the same time. One challenge we experience on a daily basis is that we have different systems that lack the ability to talk to each other. IT brings real benefits when you can offer both customers and suppliers a self-service option.

Novacura FLOW can support all around activities within business systems and beyond.